- Home

- About Us

- Products

- Talford Online Store [ NEW ! ]

- Architectural Cladding Panel

- Roofing and Insulation Materials

- Waterproofing and Damp-proofing Systems

- Concrete Repair, Floor Toppings, Surface Protection

- Acoustical Products

- Architectural Mesh

- Facade Cladding And Coating

- Wall And Floor Covering

- Fire Retardant And Fireproofing Paint Products

- News

- Project Profile

- Contact Us

Howsolpan Aluminium Composite Panel

- Home

- Architectural Cladding Panel

- Howsolpan Aluminium Composite Panel

Howsolpan Aluminium Composite Panel

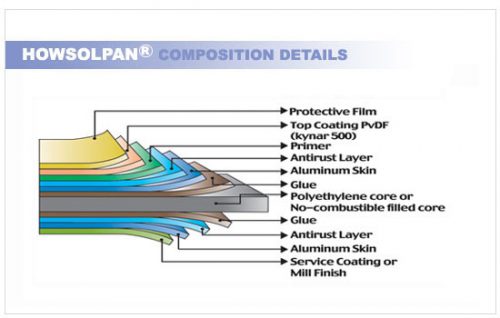

Features

Light Weight and High Rigidity

Suitable for both, new building and remodeling works as HOWSOLPAN is much lighter and less stressful to structure.

Excellent Flatness

The continuous production process and unique technology of adhesion can guarantee together with dual sandwich structure composed of two aluminum sheets and PE core, and it should not be compared with other products.

Variety, Elegance and Uniformity of Color

All colors are available as custom-made product upon clients’ request. Roll coating system of high technology offers perfect color uniformity.

Excellent Fabrication and Installation

As fabrication works such as bending, folding, bending and rounding are extremely easy, it is suitable for precise installation in accordance with designer’s intention.

Excellent Proof for Sound, Dust and Heat Conduct

Numerous cell structures between 2 sheets of Aluminum Composite Panels with high polymeric and nontoxic P.E. resin core will function for the above.

Easy Maintenance

While PVDF is excellent for the protection of building surfaces, the contaminants such as smoke and dust can be easily washable with normal synthetic detergent.

Density: 2.72 kg/m2

Tensile Strength: Rm ≥ 140N/mm2

Loop Strength: Rp 0.2 ≥ 100N/mm2

Elongation : A50 ≥ 1%

ITEM | TESTING | RESULT | REMARK |

Weight | – | 5.50 kg/m2 | – |

Density | – | 1.36 g/cm2 | – |

Tensile Strength | KS B 0802 | 5.51 kgf/mm2 | ASTM E 8 |

Yield Strength |

| 5.1 kg/mm2 | ASTM E 8 |

Elongation |

| 14.4% | ASTM E 8 |

Flexural Elasticity |

| 4080 kg/mm2 | ASTM D 393 |

Thermal Conductivity | KS L 9016 | 0.19 kcal/m.hr.oC | ASTM D 976 |

Deflection Temperature | KS F 2263 | 115oC | ASTM D 648 |

Linear Expansion | KS F 2263 | 24×10^6/oC | ASTM D 696 |

Bending Moment | KS F 2263 | 70 kgf/cm | – |

Bending Strength | KS F 2263 | 1.075 kgf/cm2 | – |

Peel Adhesive Strength | KS F 4737 | 25 kgf/25mm | – |

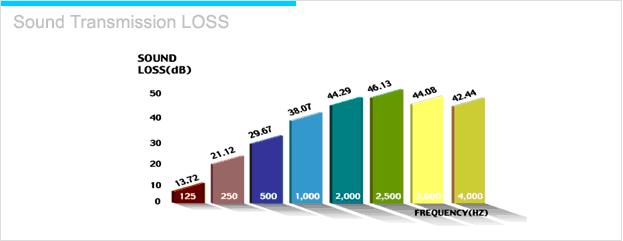

HOWSOLPAN is excellent in sound transmission loss comparing with other materials such as steel, pure aluminum and plywood, which illustrates in the chart below.

ITEM

|

TESTING

|

RESULT | REMARK |

| Gloss | 25 | ±5 | – |

| CCE | 11x11mm,6mm draw | No peel off | – |

| Pencil Hardness | 45 (Mitsubishi Unison) | H | KS D 0254 ASTM D3363-74 |

| Flexibility | T-Bending | 1-T No Crack | ASTM D 4145-83 |

| Impact Test | 1000g x Φ12.7mm x 500 mmH | No peel off | – |

| Chemical | 5% Hcl, H2SO4 x 72 Hrs | Good | ASTM D-1308-87 |

| Resistance | 5% NaOH x 72 Hrs | Good | – |

| Salt Water Spray | 5% Nacl x 5000 Hrs | Good | ASTM D-B117-90< |

Quick About Us

Links

Contact Info

Unit A, 21/F, KP Tower, 93 King’s Road,

North Point, Hong Kong

(852) 2911 0103

(852) 2911 0116

Mon – Fri 9:00 – 18:00