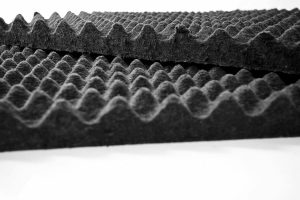

B.A.C. Eggcrate Acoustical Panel

Bonded Acoustical Cotton (B.A.C.) Eggcrate Acoustical Panel

The market’s first recycled cotton, high acoustical performance studio wall panel.

The Echo Eliminator Soundwave cotton acoustic panel is made from 85% recycled cotton and is 100% recyclable.

Features:

- Recycled Cotton (Green Acoustical Material)

- Class A – Non-Flammable (Per ASTM E-84)

- Lightweight

- Easy to Install (adhesively applied)

- Impact Resistant

- Durable

- Low Cost

- Fiberglass Free

- No Formaldehyde – No VOC’S

- Hi-Performance Acoustical Absorption

- Proudly Made in the USA

- LEED™ Eligible

Product Specifications:

| Material | Bonded Acoustical Cotton (B.A.C.) |

| Applications | Recycled Cotton Echo Eliminator Acoustic Soundwave panels are ideally suited for studios, school gymnasiums, cafeterias, classrooms, churches, multi-purpose rooms, community centers and more. |

| Density | 3lb pcf |

| Thickness | 2″ |

| Size | 2′ X 4′ |

| Color | Graphite |

Please note: Since these Echo Eliminator cotton acoustic panels have a male/female pattern (convolute), each panel is slightly different on its edge pattern. The egg crate soundproofing panels will not line up to make one large uniform pattern.

Although we take extensive precautions and purge the lines between colors, due to the manufacturing process color inconsistencies – including dye lot variations – flecks, specks, and other slight surface blemishes are unavoidable. Please call for details.

All sizes are nominal and are subject to manufacturing tolerances that may vary ± 1/8″. Exact fitting may require on site adjustment by the purchaser. Exact size and other unavoidable variables such as dye lot color variances, lighting conditions, pattern matching, directional materials, expansion and contraction due to environmental conditions. Project with exacted visual requirements and expectation must be identified for our special attention prior to ordering.

Acoustical Performance:

| Echo Eliminator™ Soundwave Panel – Sound Absorption Coefficients | ||||||||

|---|---|---|---|---|---|---|---|---|

| Mount | 125Hz | 250Hz | 500Hz | 1KHz | 2KHz | 4KHz | NRC | |

| 2″ – 3lb./cf. | A | .35 | .94 | 1.32 | 1.22 | 1.06 | 1.03 | 1.15 |